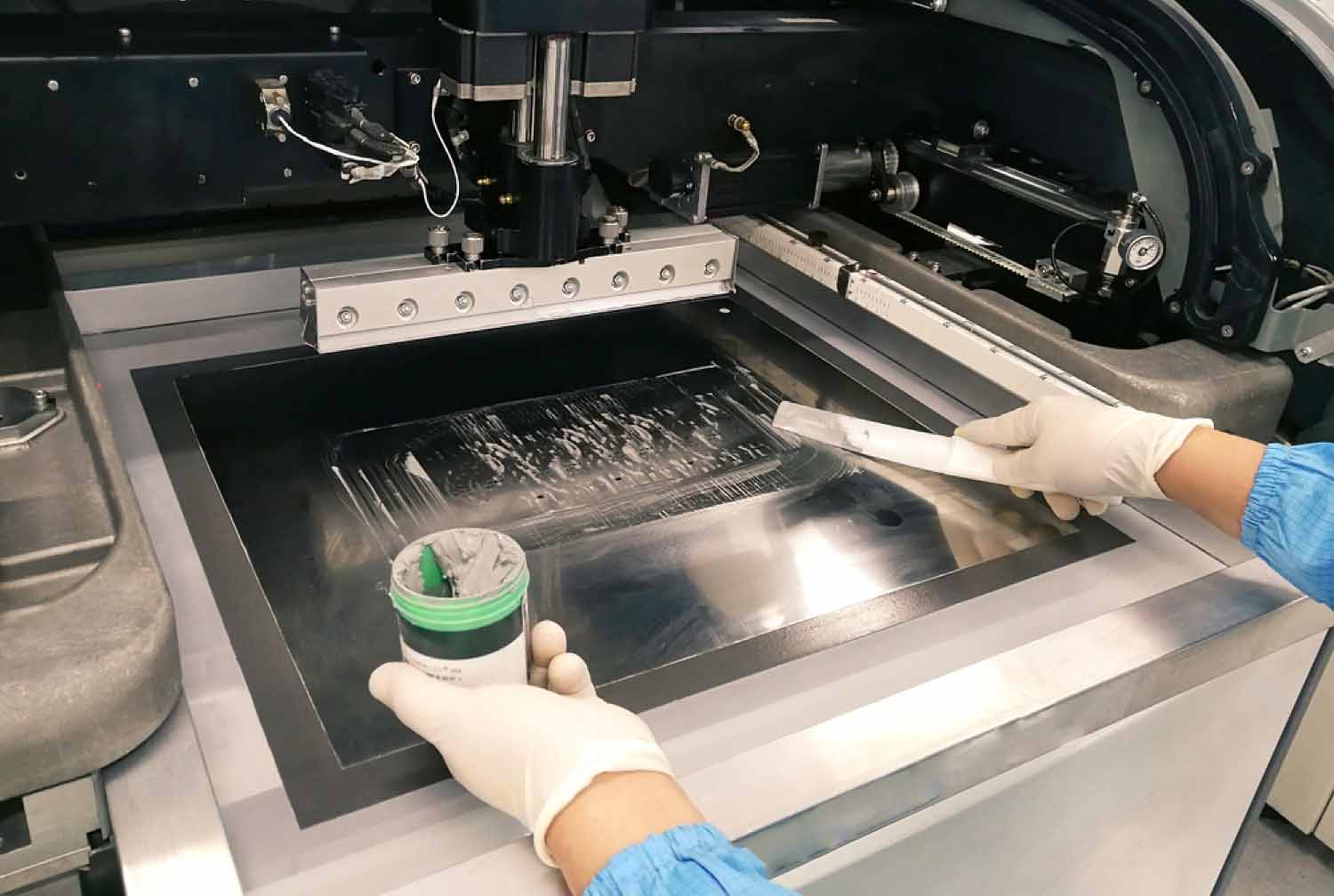

Solder Paste Printing

Solder paste printing is a key part in the SMT (Surface Mount Technology) process.The primary purpose is to apply adequate amount of solder onto the SMD pads of the bare PCBs. The most common way of carrying the process of Solder paste printing is by screen-print the solder paste through a SMD stencil and with the help of squeegee blade. SMT has a flexible requirement of viscosity but fortunately viscosity itself is a variable aspect of solder paste the solder paste's transfer efficiency from the stencil to the board during the printing process is determined by a number of variables- Squeegee Speed and pressure - The speed determine how much time is available for the solder paste to roll into aperaure cutt outs in a stencil.Inadequate pressure can cause excess solder paste sedement or low area coverage of solder pads both contributes majorly in issues like poor solder joints Squeeze Angle- the typical angle of the squeegees is set to 60° , any variation in the application angle can cause "scooping" of holder paste from the stencil apertures Stencil Separation Speed- This is the speed at which the stencil and pcb are seprated after a successful stroke of Squeegee on stencil. Print Stroke:This is the distance the squeegee travels across the stencil and is recommended to be a minimum of 20mm past the furthest aperture