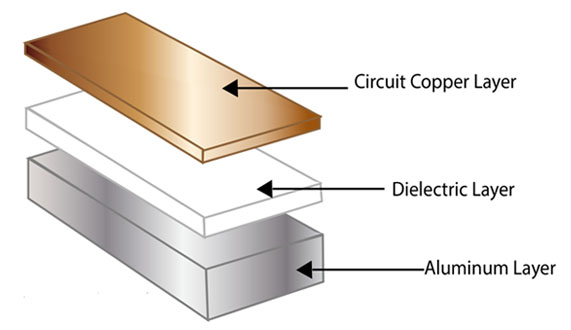

Metel Core

A Metal Core Printed Circuit Board (MCPCB) is a type of printed circuit board that contains a base metal material. The core is designed to redirect heat away from components which produce a substantial amount of heat. In contrast to FR4 and CEM3 printed circuit boards, a Metal Core Printed Circuit Board uses a base metal to increase the thermal conductivity of the PCB. The metal core is composed of a metal plate with an appropriate thickness to dissipate heat. MCPCB is available in various types based on the type of metalcore used. Aluminum MCPCB is widely used due to its low cost, lightweight, and good thermal conductivity. Copper MCPCB offers higher thermal conductivity compared to aluminum, but is more expensive and heavier. Other types of metal cores used in MCPCB include steel, nickel, and tungsten The advantages of Aluminum Core MCPCB include: Efficient heat transfer-The aluminum core in MCPCB provides a highly efficient pathway for heat dissipation, which allows them to handle higher power loads without overheating. High Mechanical Strength-The metal core layer provides rigidity and stability to the board, making it more resistant to bending, warping, and mechanical stress Pcb Layout Flexibility-This flexibility enables customized designs to meet specific application requirements.The metal core layer allows for different mounting options, including through hole soldering of components and placing surface mount components