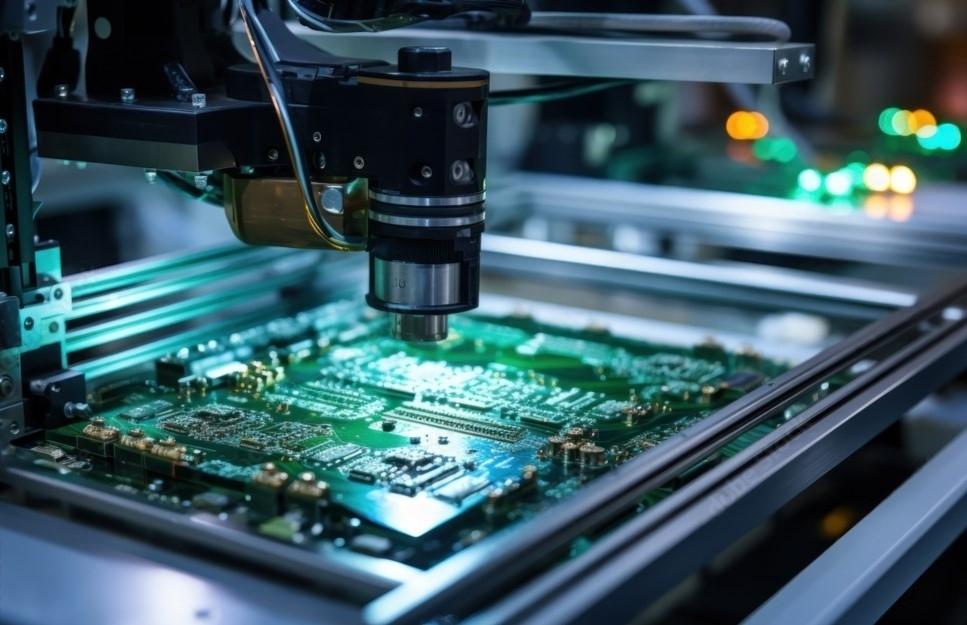

PCB fabrication

PCB fabrication- Manufacturing a printed circuit board is a complex process that begins with a product concept and ends with a fully functional PCB assembly. Along the way, a schematic captures the net connectivity, and a PCB designer lays out the circuitry to optimize electrical characteristics within the design constraints. After soldering the components onto the board and completing assembly testing and verification, the circuit board integrates into the system. The first step in the PCB manufacturing process is designing the PCB layout using specialized software. Once the design is complete, it is printed onto the copper-clad board using a process called photolithography. The board is then etched to remove the unwanted copper, leaving only the traces that will connect the components.